Wheelhouse and Maintenance: what to check and how (if at all) to intervene

THE PERFECT GIFT!

Give or treat yourself to a subscription to the print + digital Journal of Sailing and for only 69 euros a year you get the magazine at home plus read it on your PC, smartphone and tablet. With a sea of advantages.

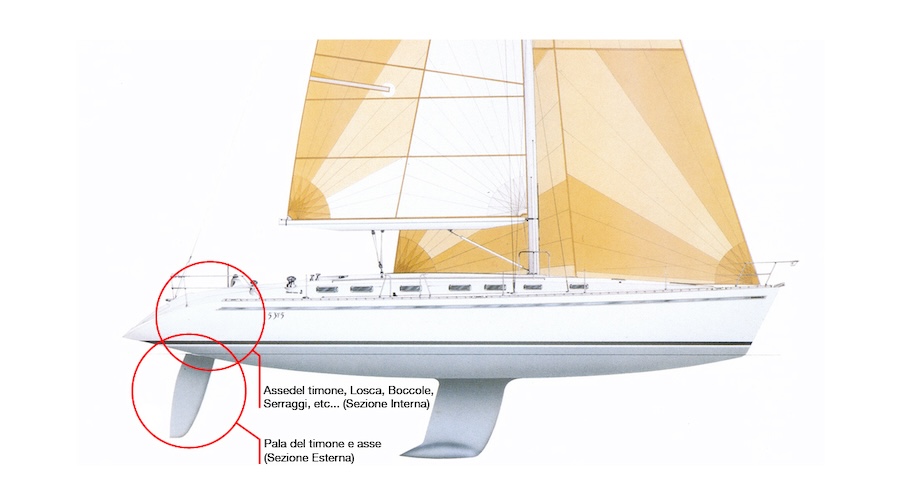

With spring almost upon us, the season is upon us. For those who haven’t already done so, now is a good time to check that everything on board is in order, especially paying attention to the less ‘visible’ elements, those you think less about and may have absent-mindedly forgotten about. It is often the ‘hidden’ components that are, in fact, worth paying more attention to. Therefore, if previously we talked about Osmosis, here we try to shed light on other areaswhere maintenance can make a difference: in this case, the rudder and its pivotal elements.

Wheelhouse and Maintenance: what to check to navigate safely

Like many of the elements on board, theentire steering system of a boat needs periodic checks, not so much because it is particularly prone to wear and tear (although, in its own way, it is), but because, in the event of problems, the consequences can be particularly unpleasant… Stories of broken planks, blades slipping out at the worst possible moment, et similia, we know of many, and they serve as a warning. With the boat running aground, then, here is a brief survey of what to check and why.

Shovel and Axis: hidden criticalities

Checking the rudder blade for impact damage is the first step. Any collisions with submerged objects, live ploughs or UFOs (Unidentified Floating Objects), can in fact damage the blade, creating cracks and splits, thus causing seepage and subsequent damage to the internal composites. Regardless of shocks, water seepage into the blade-a not uncommon fact-should always be checked, as rudders often have hollow spaces inside or are filled with synthetic foam. This, very commonly, predisposes them to osmosis.

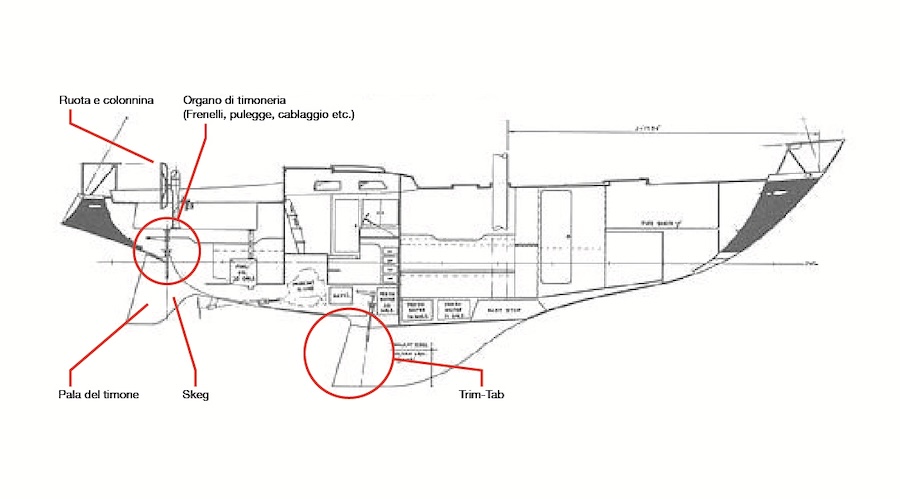

With the exception of those who had external rudder (hinged to the transom, for which checks will be easier), any shocks to the blade may compromise the shaft, thus leading to relative checks of the latter as well. The rudder shaft, in fact, is a solid or hollow tube made of metal material-aluminum, steel, or, in some cases, fiberglass-encapsulated in the blade and passing the hull inside the looseness, or case. In the case of particular shocks and/or stresses, it is possible that the shaft will show tortures or distortions, damage that will need to be remedied by straightening, reinforcing, or replacing the shaft itself. In this eventuality, however, the repercussions of the impact could extend to other components as well:

- The area of attachment between the axle and the hull (lower outlet of the loch) is often one of the critical points, especially in cases where the blade is hanging and particularly deep. Here, potentially, a collision could result in cracks or waterway openings, cases in which immediate remediation is essential. Any damage is visible to the naked eye and possibly even by slipping the rudder off and removing the bushing to inspect the joining points.

- The blade head itself is another hidden fragile point. Due to an impact, in addition to notching, the blade may also have cracks or seepage at the head where the axle exits, compromising the structural integrity and/or proper union between the two parts. A good check consists of locking the rudder (tiller/wheel) and pushing the blade in its different directions. The presence of excessive clearance between blade and axle is a potential symptom of structural damage, internal corrosion, or deformation of the parts.

- Equally dangerous, any forcing of the axle could damage the axle’s locking systems (generally found in the upper bushing area), thereby compromising those very elements that prevent the axle (and thus the blade) from slipping off.

If the skeg is present, however, it is still good practice to check that the union point between the blade and the axle is healthy: the risk that the axle may be damaged internally to the blade, or that it may spin loose inside the blade, are still worth considering. Even the skeg, however, is not immune to possible problems, so boundary marks or signs of deterioration of any internal metal parts should be checked.

Wheelhouse. Bushings and fasteners: why maintenance is important

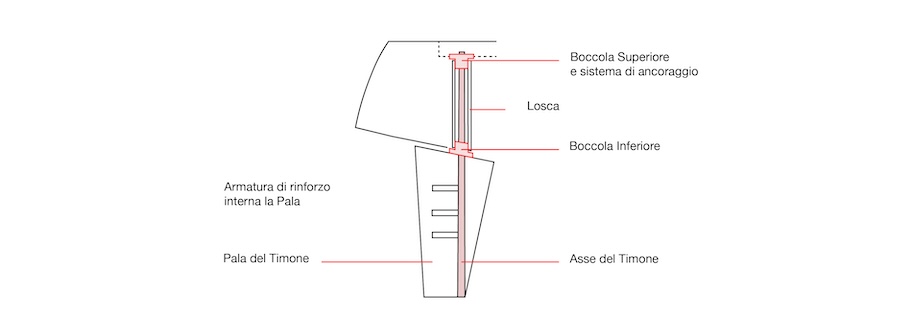

In the absence of impact damage, a good deal of verification still needs to be addressed. In fact, the rudder shaft is a delicate element in its own way and subject to not inconsiderable stress, due to both the resistance that the blade places on the water, the vibrations that inboard motors create, and the turbulence that the propeller can impose on the blade itself. In light of this, particular attention should be paid to two elements: the bushings and the axle anchoring systems.

Generally, in fact, at the two ends of the luff we find the bushings, key elements for the proper functioning of the rudder. A first bushing, the lower one, is inserted from below and attached to the hull by specific adhesive systems or screws. It is she to prevent the entry of water and provides the exit point of the shaft, supporting the shaft itself and facilitating the rotation of the blade. The second bushing is the upper one, which in turn is important as it maintains the orientation of the axle (fundamental) and, in addition to supporting its lateral stresses, houses its locking system, preventing the axle from slipping off, and with it the blade. The most common problem at this juncture is bushing wear, leading to two symptoms and two potential problems.

A first sign is increased resistance to blade rotation, easily identifiable with a tiller rudder, less so with a wheel rudder*. In this case, it will be a good idea to check all components and, if necessary, to pull the rudder out to check the condition of the bushings, which are probably deformed. Far more risky, however, is the presence of ‘play’ on the rudder shaft (more than 1-2 mm, visible by placing pressure on the blade in a lateral direction). This is far more risky in that, in the long run, it can directly damage both the shim and the locking systems of the axle itself-similar to what a warped axle would create.

Checking the condition of the bushings is thus essential to navigate safely and, more importantly, to take action before problems decide to present themselves.

*In the case of wheel systems, hardening of the rudder may also be due to wear of some components of the internal circuit, which in turn should be inspected and maintained regularly. In order not to avoid surprises, brakes, axle sector (often and in material different from the axle so it is also good to check for traces of galvanic corrosion), pulleys and cables included, should always be checked, not only because of wear issues, but also because of the potential loosening that engine vibrations could bring to the anchoring systems of these.

Are you looking for or want to sell a Classic Boat?

- If you are looking for or want to sell a Classic Boat, remember our Used Boat Market(HERE), the ideal place for anyone looking for a Classic Boat to buy and/or, even more so, the ideal platform for those who have a desire or need to sell their vintage gem. If you have a Classic Boat to sell, or if you were looking for one, remember the Marketplace. Using it is as simple as it gets.

- Want to learn more about the world of Classic Boats (1967-1998), the iconic boats of the period, the legendary designers, the stories and races of the “golden age” of sailing? Check out our section dedicated to Classic Boats!

Share:

Are you already a subscriber?

Ultimi annunci

Our social

Sign up for our Newsletter

We give you a gift

Sailing, its stories, all boats, accessories. Sign up now for our free newsletter and receive the best news selected by the Sailing Newspaper editorial staff each week. Plus we give you one month of GdV digitally on PC, Tablet, Smartphone. Enter your email below, agree to the Privacy Policy and click the “sign me up” button. You will receive a code to activate your month of GdV for free!

You may also be interested in.

Old boat makes good board! The legendary Fraglia schooner has been “re-launched” after 50 years.

Desenzano, Lake Garda, home of the FVD, Fraglia Vela Desenzano. A Lake classic replicates its launch 50 years after the first time. It is the Fraglia schooner, a light alloy school schooner, the first in Italy to ever be built

Classic Boat Cult | 6 meters overall: agile, compact and exceptional

Small, compact, exceptional. Three words to best describe 7 boats that, combined in size, we believe are absolute must-have gems-both for culture and for potential purchase. In fact, in this our review of the great Classic Boats of the past,

5 out-of-the-box ideas seen at the Genoa Boat Show for “sailing” without a boat

The Genoa Boat Show , for a few days, was transformed into a microcosm. A place where size does not matter (not only for boats) and where figures take on relative meaning. Those who live by the sea know

Classic Boat Club | Comet: 5 hulls celebrating Comar’s signature excellence

Forlì, 1961: Sipla, a small fiberglass Flying Junior manufacturer, is born. These are the dawn of large-scale production, and the new company soon becomes a pioneer in naval production in vtr. Growth is steady, small masterpieces such as Van de