Solaris 74 RS (22 m), how to sail around the world in total comfort

THE PERFECT GIFT!

Give or treat yourself to a subscription to the print + digital Journal of Sailing and for only 69 euros a year you get the magazine at home plus read it on your PC, smartphone and tablet. With a sea of advantages.

A semi-custom bluewater perfect for touring the world, easy to conduct, with all the advantages of a “raised saloon” (i.e., raised square) but without sacrificing the lines and elegance typical of a “flush deck.”

Solaris 74 RS (22 m) – Ultimate Bluewater

The Solaris 74 RS (22.00 x 6.10 m) was born with this ambition, which is far from easy to put into practice. We tell you how the Italian shipyard succeeded in the feat. The end result, “live,” you will soon be able to judge for yourself. The first hull, currently under construction, is scheduled for delivery in late 2023.

Solaris 74 RS – The background of the shipyard

Let’s start by saying that Solaris, over the years, has often measured itself against hulls of this size, and iconic boats, real milestones in the Aquileia shipyard’s production, have come out of them. Just think of the Solaris 76 “Zero” built in 1995 to a design by Doug Peterson (the designer of the Luna Rossa “Silver Bullet” of the 2000 Cup, just to mention one of his designs!), or the 72 DH, built in 2003 also to a design by Peterson, a true “globetrotter” with which navigator Enrico Tettamanti explored the globe, from the poles to the equator.

Instead, from 2013 is 72 Classic, signed by Argentine Javier Soto Acebal, who together with Solaris started a long and fruitful collaboration and who, precisely, curated water lines, hull lines and sail plan of the new Solaris 74 RS. There is no shortage of experience at Solaris.

But you don’t live by experience alone, and the 74 sees a new entry when it comes to interiors. Lorenzo Argento, the Italian designer on the crest of a wave with a history ranging from production boats (First 53, Oceanis Yacht 60, First 44…) to custom (YYachts, Wally…).

Solaris 74 RS – Construction

Hull and deck construction, interiors, weight and stability calculations, water system, plumbing, electrical and electronics are, as always, by Solaris’ in-house team.

The materials used and the type of construction are a function of the hull ‘s light weight (40.6 t light displacement with 3.50 m cast-iron fin), but without sacrificing in any way its strength and rigidity. The deck and hull are designed like everything else on the boat for large loads and durability. Deck and hull are made from female mold.

Great use is made of vinylester resin from epoxy base, with overlapping states and unidirectional reinforcements on the centerline of the hull to increase longitudinal stiffness. The sandwich structure è a closed-cell PVC. Nothing is left to chance: the density of the foam (35 mm thick) is higher in the bow sections of the hull bottom (130 kg per cubic meter) to increase wave impact resistance (slamming). The inner skin of the hull is resin infused.

Solaris 74 RS – Exterior

Opting for a boat with “raised saloon” (which gives its name to the acronym, RS) favors livability and light below deck (as well as create the space amidships for the engine room, benefiting stability and ease of inspection): But it brings with it a problem to be solved. That of the outside lines.

Soto Acebal has reduced the impact of the raised deckhouse by not only designing it as “streamlined” as possible, with rounded lines and no hard angles, but has implemented the “flush” effect through the deck line that plays on two levels, with the higher one towards the stern.

The Solaris 74’s water lines are modern, with buoyancy at the bow ensured by a small edge that disappears down the hull to an extremely round stern that opens to two rudder blades. Two independent guidance systems that provide redundancy and safety. The rudder axles are connected with a tie rod that allows each wheel to act on both rudders.

The deck design features a completely clear bow area (interrupted only by the rail for the self-tacking jib) and a large cockpit with full-width rudder wheels: The off-axis entry, to starboard, leaves the cockpit table to port free, which with a lift to the stern allows for a substantial sunbathing area and back positioning for guests in the cockpit.

From the helmsman’s station, thanks to electrified winches, you can conveniently manage sail adjustment and keep an eye on all on-board instruments. The mainsail sheet point is central and is operated by a central electric winch on a pedestal.

The aft tender garage (which can accommodate boats up to 4 m) is very spacious, with a fold-down bridge that creates the now-classic sea terrace, perfect for bathing and diving. Boom and mast are made of light aluminum alloy while the rigging is made of rebar.

Solaris 74 RS – Interior

Let’s go below deck to find out how Lorenzo intervened, but first let’s summarize, in four points, the yard’s inescapable philosophy regarding interiors.

-

- All carpentry work must be done in accordance with nautical tradition

- Any free space is used as a locker

- Lines should be simple and clean

- The corners of hatches, bulkheads, seats, and all furniture are rounded off

“On the Solaris 74 RS,” Argento tells us, “we worked hard to soften the shapes as much as possible and have maximum brightness. For example, we defined a maximum quota of live wood (All furniture is finished in oak wood, ed.) By inserting much more white. We also intervened with low, softened-radius paneling that would wrap around square and booths“.

Then there are some finesses: since, as we explained to you, every free space on board must become a stowage, “some of the decorative panels sometimes become movable: to open them, instead of providing the classic button on the vertical wall, we placed it on the horizontal plane. A solution that contributes to the overall sense of cleanliness and orderliness“.

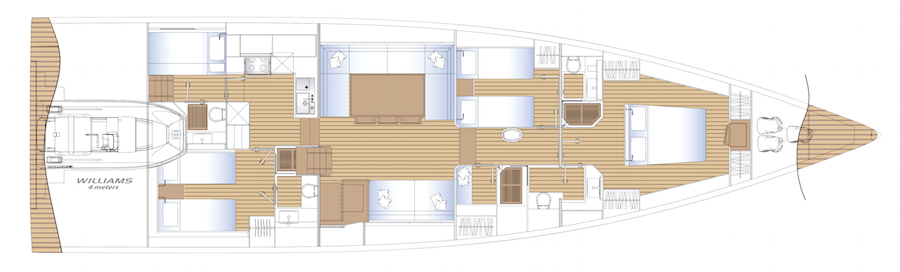

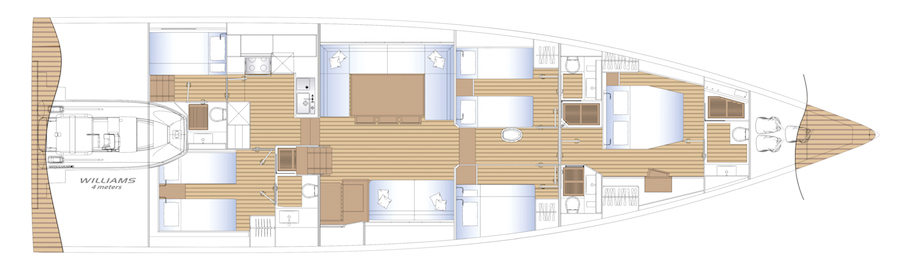

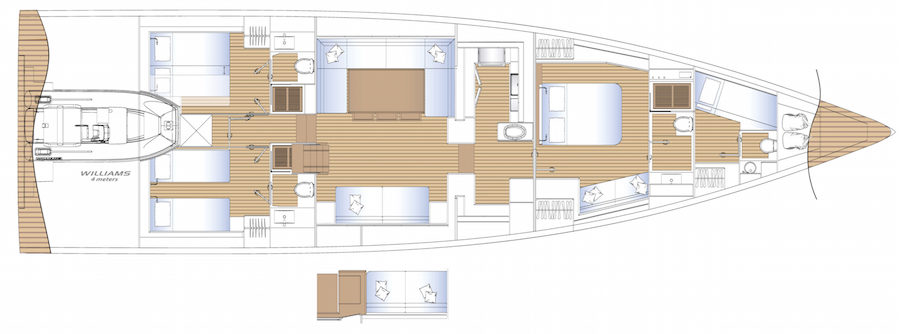

We come to the available layouts, three, characterized by differences but with ample space for 3 or 4 double cabins plus crew cabin with separate toilet.

All of them, in common, have thehuge dinette (sofa to port with table, linear contra-dinette opposite the dinette, chart table with stowage and seating facing forward), as bright as only can be on a raised saloon, and the calavele in the bow. As anticipated, the engine compartment is located under the salon dunnage, accessible by a hatch with neoprene seals and acoustically insulated by a special a 45 mm barrier against various sound frequencies.

Layout

The first layout option features a large forward master stateroom with island bed, closets, lockers, desk on the forward bulkhead, full-height furniture, and bathroom with dedicated shower stall, followed aft by a double and bathroom with shower. Aft, to port is the lowered L-shaped galley (forward of the crew cabin with double berth and independent bathroom), to starboard is a double cabin accommodates also served by a bathroom.

The second layout includes the slightly smaller master stateroom for the benefit of two double cabins aft (with bunk beds the starboard one) both served by bathrooms with showers. Other spaces unchanged from the first layout.

Instead, the last configuration features the crew cabin forward of the owner’s cabin and a lowered “mast foot” galley. Two guest cabins with bathrooms are located in the stern.

“In the ‘traditional’ layout involving the galley aft,” Argento explains, “we pierced the forward bulkhead bordering the dinette, lightening the shapes and effectively creating a double volume that becomes a bookcase in the square and exploiting an otherwise unused volume of the forward guest cabins. Indeed, this very extra volume, can be used in terms of both purely decorative, but also as an object holder.“.

Data Sheet

Overall length 22.00 m

Length at waterline 20.76 m (light displacement)

Beam max. 6,10 m

Draft 3.50 m standard(2.90 m optional)

Light displacement 40.6 t

Ballast(cast iron fin 3.50 m) 10.5 t

Sup. sail (100% bow triangle) 250 sq. m.

Sup. Flake 90% 102 sq. m.

Sup. Mainsail 138 sqm

Volvo Penta D4-175 hp engine

Transmission Axle line bronze stand with thrust bearing

Generator (optional) Cummins Onan 17.5 kW

Fresh water tank 1200 l

Fuel tank 1400 l

RINA Certification Class A Oceanic

Javier Soto Acebal Project

Interior Design Lorenzo Argento

Construction Solaris Yachts

Edited by Eugenio Ruocco

Share:

Are you already a subscriber?

Ultimi annunci

Our social

Sign up for our Newsletter

We give you a gift

Sailing, its stories, all boats, accessories. Sign up now for our free newsletter and receive the best news selected by the Sailing Newspaper editorial staff each week. Plus we give you one month of GdV digitally on PC, Tablet, Smartphone. Enter your email below, agree to the Privacy Policy and click the “sign me up” button. You will receive a code to activate your month of GdV for free!

You may also be interested in.

Old boat makes good board! The legendary Fraglia schooner has been “re-launched” after 50 years.

Desenzano, Lake Garda, home of the FVD, Fraglia Vela Desenzano. A Lake classic replicates its launch 50 years after the first time. It is the Fraglia schooner, a light alloy school schooner, the first in Italy to ever be built

VIDEO – Ubi Maior Italia, when a new company is born from a bit of madness

A boat ride in 45 knots and a pinch of madness: these are the ingredients of a story that speaks 100 percent the language of Made in Italy. A story that starts from the heart of Tuscany and has reached

Swan Alloy 44: the new 44-meter aluminum supermaxi

Nautor Swan has unveiled the new Swan Alloy 44, a 44-meter aluminum sailing supermaxi. The first example is scheduled for delivery in summer 2028, with the hull built in the Netherlands and completion in Viareggio. The first owner will be

VIDEO – Stem 50 (15.85 m), the 100% Italian aluminum bluewater

We can almost call it “bluewater mania,” because in this 2025 many novelties in sailing come from this type of boat: after the Bluewater 56, the CNB 62, comes a 100% made in Italy boat, which is also a first