1984. The best boats in the world were the Stars of Lillia

THE PERFECT GIFT!

Give or treat yourself to a subscription to the print + digital Journal of Sailing and for only 69 euros a year you get the magazine at home plus read it on your PC, smartphone and tablet. With a sea of advantages.

Welcome to the special section “GdV 5th Years.” We are introducing you, day by day, An article from the archives of the Journal of Sailing, starting in 1975. A word of advice, get in the habit of starting your day with the most exciting sailing stories-it will be like being on a boat even if you are ashore.

The best boats in the world were the Stars of Lillia

Taken from the 1984 Journal of Sailing, Year 9, No. 1, February-March, pp. 69-71.

In a former spinning mill on Lake Como, an outstanding craftsman, “Meco” Lillia, built the queen of Olympic classes, the Star. They came from all over the world to have a Lillia. We tell you a beautiful story of passion and ingenuity made in Italy.

The Starss: inspiration and computers

From craftsmanship to computerized scales to vacuum layering. Meco Lillia, the Stars, now, builds them this way.

At the beginning of the century it was a spinning mill employing two hundred people. Thereafter it experienced many decades of neglect, until Meco Lillia had the gimmick of buying it and turning it into one of the best-equipped shipbuilding yards in Star, the queen and veteran of the Olympic classes.

The former spinning mill, or rather the new Lillia shipyard, is located in Musso, in the northern part of Lake Como, an area that has gone down in history for having marked the last moments of the Fascist regime. The shipyard, located on a hillside, preserves intact the exterior architectural structure of the old spinning mill, while internally the two thousand square meters, arranged on three floors, have been partly renovated to adapt them to the requirements demanded by boat building.

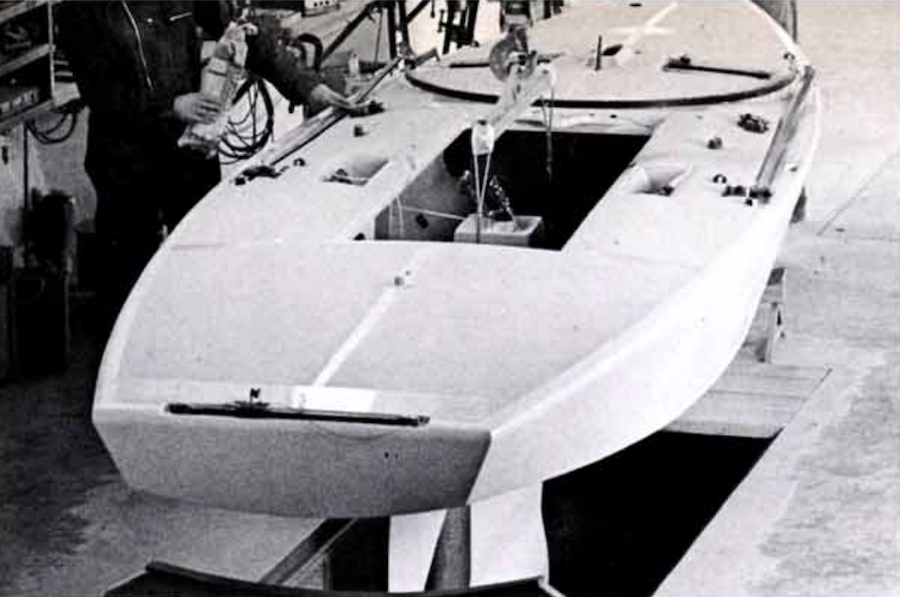

The second floor is used for storage. Hull and deck of the Star and Dinghy 12-footers are built on the second floor of the shipyard. After being assembled and taken out of the mold, the hulls are transferred to the ground floor where, in the case of the Star, the bulb, rudder, and all rigging are assembled.

But let’s look in detail at how Lillia’s Star is built, which quickly became known and appreciated overseas. Lillia has linked his name to three versions of the Star that marked somewhat of a “historical” turning point in this class. With the passing of his brother Gianni, Meco Lillia took over the running of the yard in 1981. The first innovation was the self-draining Star with two versions of double bottom: height 10 cm and 20 cm.

Meco, who in the meantime began to use the collaboration of Remo and Niki Politi, did not stop with the double-bottomed version, but “commissioned” engineer Gilberto Colombo (who already with Gianni Lillia was in charge of the design of the Stars) for a new boat that had to be stiffer than the previous model.

Star’s new model is born

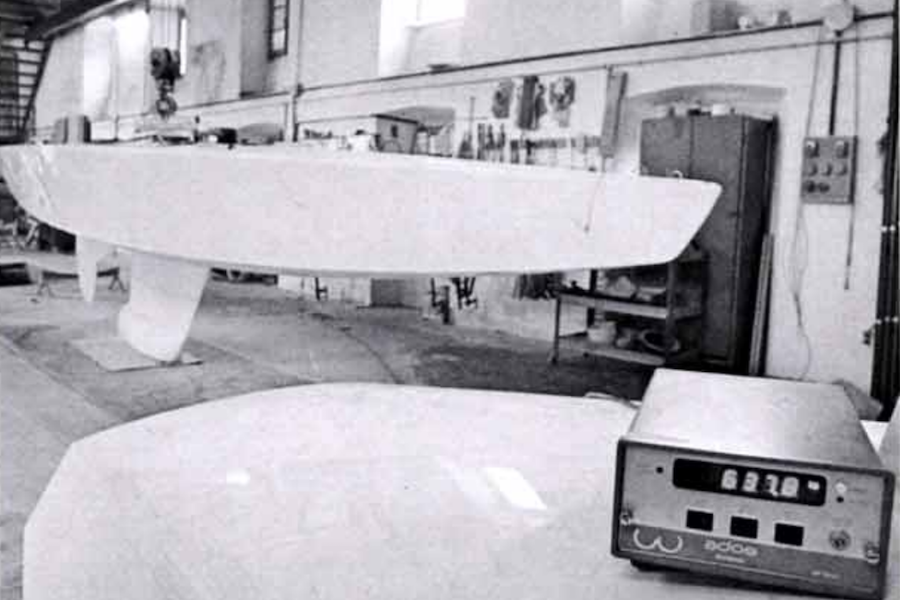

Thus was born, at the end of 1983, the latest Star model, made with cutting-edge technology. But let Lillia himself introduce us to this boat: ” Our Star is constructed of fiberglass sandwich and Airex, a special type of PVC, using the vacuum system that allows us to achieve perfect bonding of the sandwich and meticulous control of resin distribution in the mold. Both the deck mold and the hull mold run on rails below which is placed an electronic scale connected to a computer. This scale allows the weight of the hull and deck under construction to be continuously monitored. The double deck is made directly on the hull, according to the needs of the crew, with panels of Honeycomb, which also form the stiffening structure. Any water that may be embarked is piped to the middle of the boat in a special “channel” and drained. Condensation that may form in the watertight compartments is removed through special drains. The deck has also been redesigned with a different slope toward the inside of the cockpit and a different anti-slip design.”

The two prototypes of these boats placed first and second in the Bacardi Cup, one of the world’s most important Star Class events, with the U.S.-based Menkart and Denmark’s Christensen, respectively. After being assembled, the Stars move to the ground floor, where the bulb and rudder are mounted and the final finishing of the boat is done. The last stage of processing involves passing the Star through a “special “pit” that allows the rigging to be assembled at “ground level.”

“With the pit system,” says Lillia, ” we save a lot of 0time in equipping the Star whose equipment counts four hundred parts. Also on the ground floor are the rudder and bulb machining and Dinghy rigging departments, the workshop for machining all metal parts, and the room where the assembly of masts from the United States is completed. But that’s not all: once the Stars are finished, they are weighed on a scale similar to the one found in the layering department and the mast is assembled, an operation, this, possible within the shipyard.

Meco Lillia, who in just two years has managed to revive a tradition that began in 1957, is not yet satisfied with the successes of his yard (which sells Star in the United States, Canada, Brazil, Argentina, France, England, Denmark, Finland and Sweden) and continues to “churn out” and implement new ideas. In fact, a test tank is under construction outside the yard. But the most interesting novelty is the construction in Pianello, in the old 400-square-meter shipyard by the lake, of a permanent second-hand and test center for the Stars. Here customers can see and try both new and used boats.

This center, which has a fixed and a mobile crane for launching and hauling the Stars, will also become an important reference point for Lillia Shipyard’s top helmsmen. Here Cassinari, Roberti, Scala and U.S. Menkart are already testing the new boats. Lillia’s Stars are also used by other strong helmsmen such as Americans Diaz and Wennerstrom, Brazilian Nabuco, Danes Chriestensen and Jensen, and Englishman Boyce. Lillia also plans to build a dinghy on which he would not comment. Will it perhaps be the mold of an Olympic class that will go alongside that of the Star in the former Musso spinning mill?

Luigi Ciccarone

Photo by Livio Fioroni

Share:

Are you already a subscriber?

Ultimi annunci

Our social

Sign up for our Newsletter

We give you a gift

Sailing, its stories, all boats, accessories. Sign up now for our free newsletter and receive the best news selected by the Sailing Newspaper editorial staff each week. Plus we give you one month of GdV digitally on PC, Tablet, Smartphone. Enter your email below, agree to the Privacy Policy and click the “sign me up” button. You will receive a code to activate your month of GdV for free!

You may also be interested in.

Michele Molino, nautical engineer with the sea in his vein

On the occasion of the 50th anniversary of the Journal of Sailing, the great excellences of the sailing world tell their stories and reveal their projects. In this column, discover all the companies and people who have made important contributions

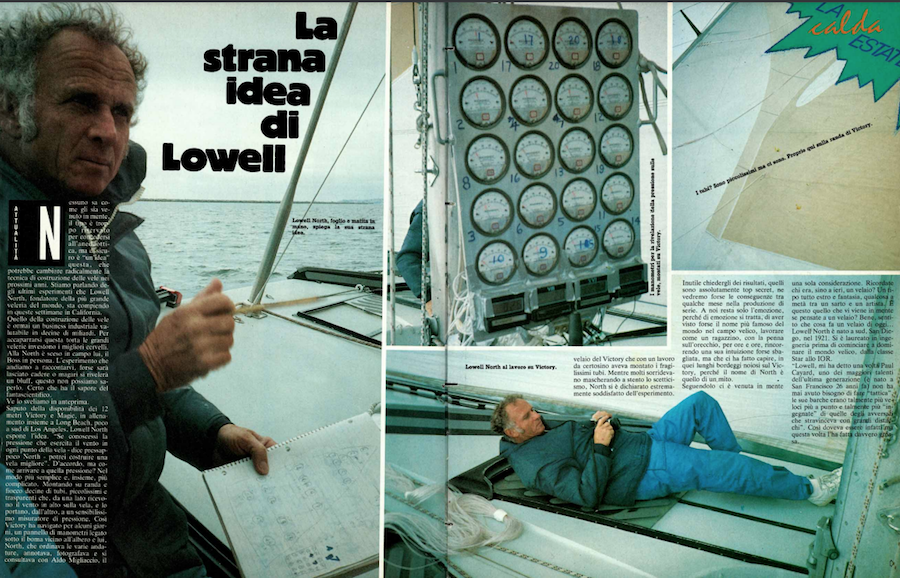

1985. The sails of the future are being born. The GdV is in, with Lowell North

Welcome to the special section “GdV 5th Years.” We are introducing you, day by day, An article from the archives of the Journal of Sailing, starting in 1975. A word of advice, get in the habit of starting your day

Marinedi, the integrated hospitality system

On the occasion of the 50th anniversary of the Journal of Sailing, the great excellences of the sailing world tell their stories and reveal their projects. In this column, discover all the companies and people who have made important contributions

Naval revolution goes through Judel/Vrolijk study

On the occasion of the 50th anniversary of the Journal of Sailing, the great excellences of the sailing world tell their stories and reveal their projects. In this column, discover all the companies and people who have made important contributions